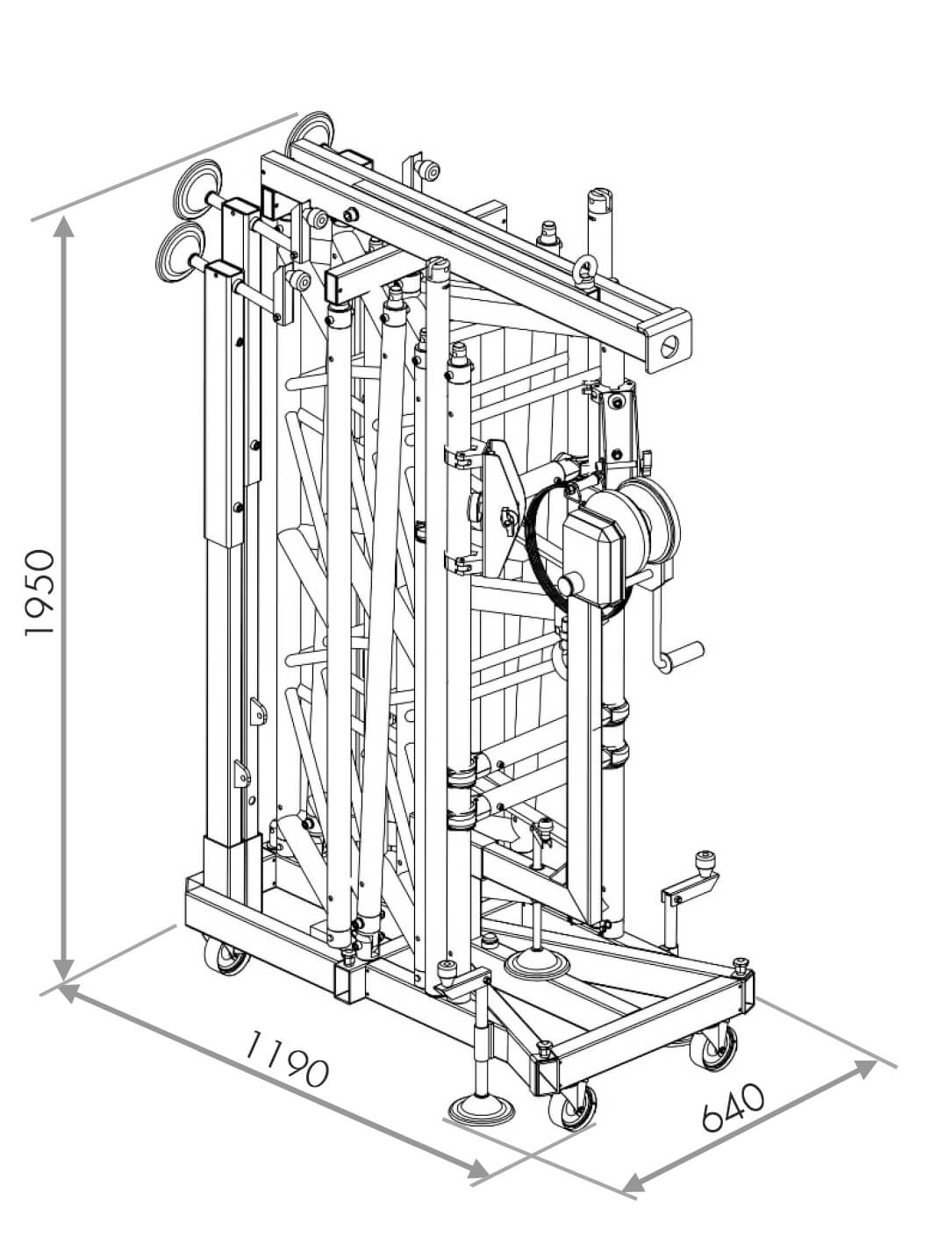

Compact design Line Array Tower

(Stowed volume: 1.49 m3)

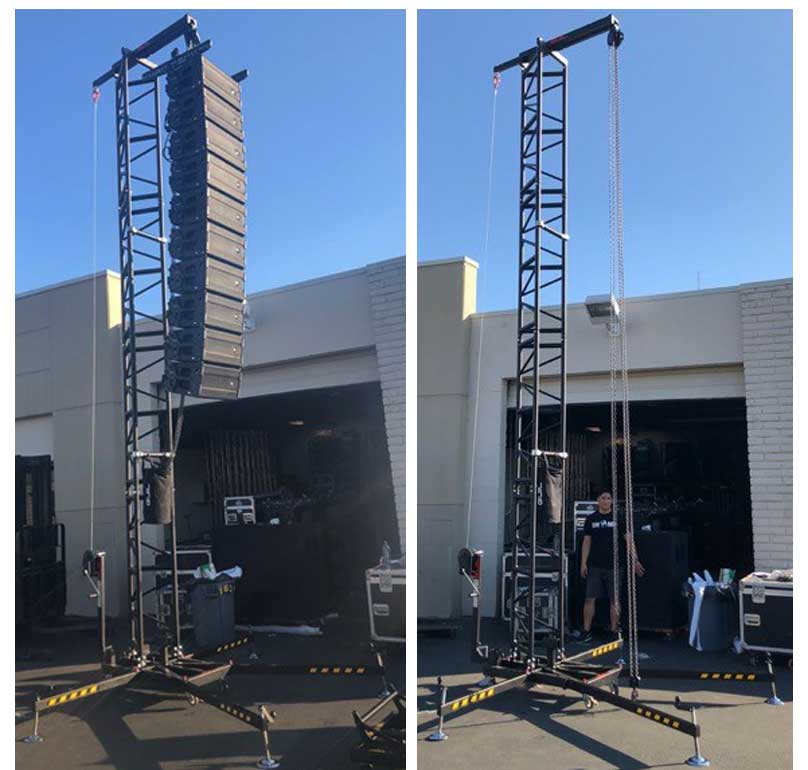

Rigging tower (Line Array Systems) specially designed to reliably lift Line Array Systems of up to 500 kg (1103 lb) to a maximum height of 6.43 metres (21.10 ft).

Its innovative compact design with castors (one complete unit has a volume of 1.49 m³) gives the TMD-545/N Rigging tower easy handling and manoeuvrability, reducing storage space. It is the perfect solution for touring!

The TMD-545/N comes totally equipped with all components and elements necessary for use: complete operating structure, with chain hoist for lifting and winch for set-up, etc. You get a complete tower, ready to go straight out of the box. Its meticulous design offers easy assembly and handling, and the whole tower occupies only 1.49 m3 in one single block when stowed. The TMD-545/N is supremely manoeuvrable, easy to store, transport and position, and offers safety, strength and reliability for the user. One of the most convenient and functional towers on the market, it is the perfect solution for touring!

The rigging tower TMD-545/N is supplied with an interactive application “TMD-545/N APC”, for its use outdoors, establishing the maximum wind speeds depending on your PA System.

| SPECIFICATIONS | TMD-545/N |

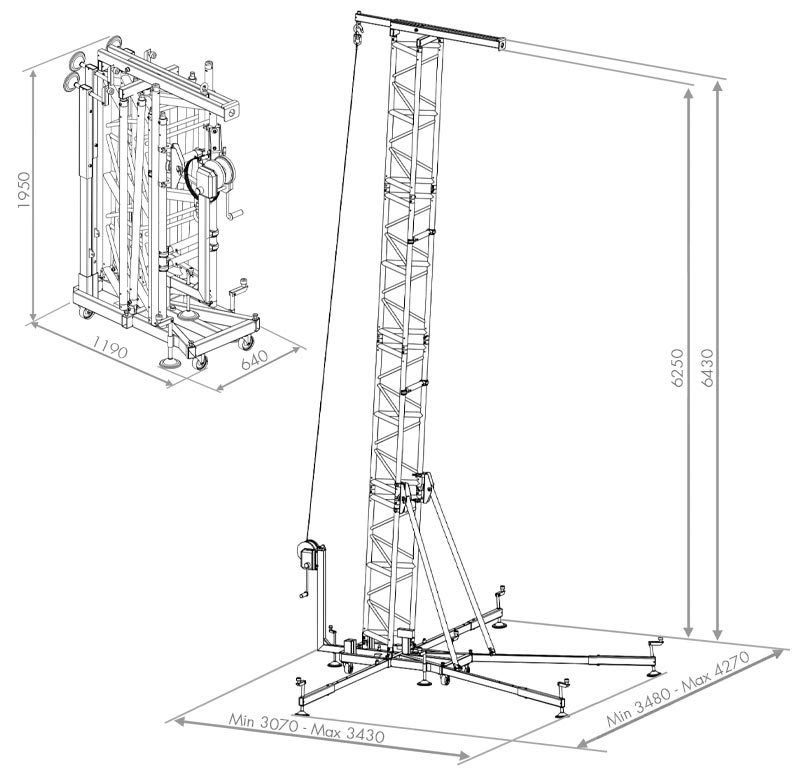

| Maximum Overall Height: | 6.43 m I 21.10 ft |

| Maximum Working Height: | 6.25 m I 20.50 ft |

| Maximum Load: | 500 kg I 1103 lb |

| PA System lifted by: | 2000 kg Chain hoist (Included) |

| Tower Structure lifted by: | Auto Brake Winch: AL-KO OPTIMA 901 (Included) |

| Mast Sections – Stacking Truss: | 500 x 500 mm (4 units. Lenght: 1500 mm) |

| Material: | Aluminium (alloy 6082-T6) & Steel. BLACK Finish |

| Folded Height: | 1.95 m I 6.40 ft (Compact Design) |

| Volume: | 1.49 m3 I 4.86 ft3 (64 x 119 x 195 cm). Everthing in 1 piece |

| Use: | For OUTDOOR and Indoor use |

| Certified for outside use: | According to: DIN EN 13814 |

| Checked for wind speed up to: 8 Beaufort | |

| Complies with Standards: | DGUV 17 & 18, DGUV Rule 115-002 (Formerly BGV-C1) |

| DIN EN 17206 (Replaces DIN 56950-1), 2006/42/CE | |

| Net Weight: | 190 kg I 419 lb (All components included) |

| Interactive application: | “TMD-545/N APC” (Included) |

Maximum working height: 6.25 m (20 ft 6 in) / Maximum load capacity: 500 kg (1103 lb)

QUICK AND EASY SET-UP: GUIL are well-acquainted with the difficulties met by assemblers who need to set up sound systems like these for outdoor events, and have designed the TMD-545/N, which can be quickly and easily set up by just one person. The winch allows the technician to lift the assembled truss sections upright without needing four or five people to help. Just two minutes help from a colleague to begin to raise the mast is sufficient, and similarly to lower it for takedown.

PRACTICAL & COMPACT FOR STORAGE AND TRANSPORT: With its ingenious design and high capacity, its quick assembly and compact stowed size that fits in just one unit of 1.49 m3, and its convenient transport and handling, the TMD-545/N can be considered one of the most functional line array structures on the market. Just one fitter can transport the TMD-545/N, using the handlebar to direct it, from the lorry to the set-up location. That’s convenience for you! The TMD-545/N is ideal for touring and periodic shows, as well as town or school events, and for any other infrequent use where storage space is also an important factor.

DESIGNED FOR OUTDOOR EVENTS: The TMD-545/N was specially conceived for outdoor use (though, naturally, it may also be used indoors), and is supplied with an interactive application, the “TMD-545/N APC”, which helps the user to calculate the maximum permissible wind speed, according to the EU norm (EN 13814) for this purpose, taking into account the weight and height for the line array to be used on each occasion.

MAXIMUM SAFETY AND RELIABILITY: GUIL always takes very seriously the safety of our users and those enjoying the events where our lifters are being used. This is why we work only with the most state-of-the-art specialised technology and first-class materials to manufacture the devices that our engineers create, and the TMD-545/N follows this rule in every way. The certified resistance and stability of this tower, manufactured to fly line array of 500 kg weight to a height of 6.25 metres, are achieved by its intelligent design and reinforced construction, and ensure the protection of both the speaker system itself and, of course, of the people near the tower at the event.

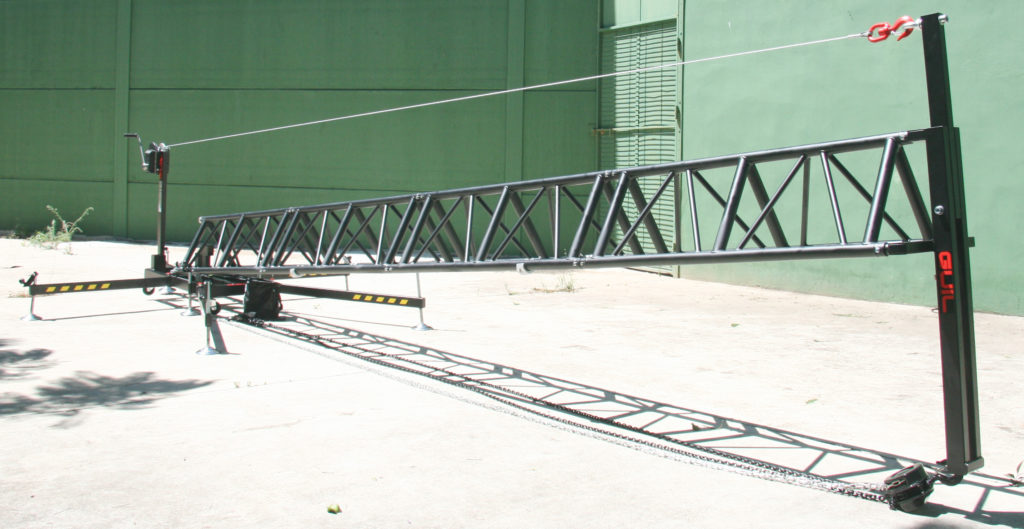

The TMD-545/N rigging tower has been designed to be set up as quickly and easily as possible, while safety is also of maximum importance to GUIL. The front legs and side stabilisers of the tower are inserted into their housings and held in place with locking pins. The truss sections of the TMD-545/N are designed to be assembled horizontally on the ground, before being attached to the hinges on the base of the tower and raised into a vertical position with the winch. The seven screw jacks on the legs, side stabilisers and base, and the spirit level on the base are then used to level the tower before use. This system guarantees quick and easy assembly and take-down of the tower, which can be carried out by only two people.

The Line Array System will be lifted by the hand-chain hoist (Ref. POLI/4) which has a certified lifting capacity of 2.000 kg (4409 lb) (CE). It has 6 m load and hand chains, which make lifting the Line Array system effortless. A BLC-01 Reinforced Chain Bag is also supplied.

Stacking truss stages are used on the TMD-545/N in order to create an easy-to-assemble high-strength exterior use lifting mast which would also be quick to assemble and take up as little space as possible for minimum storage and transport space.

TRUSS SECTIONS: Four 1500mm sections of 500mm x 500mm stacking truss compose the mast of the TMD-545/N, designed to be stacked together vertically on the base for storage and transport. The tower comes with two strengthening braces to reinforce the sections, and the truss sections are connected with zero play for maximum security. The sections stack together on the wheeled base for storage and transport to occupy a mere 1.49 m3 when stowed.

REINFORCEMENT – BRACE BARS: The trusses and the front legs are connected for reinforcement with two brace bars, which are secured with double clamps to the trusses, forming a strong and stable unit.

The head block consists of two 1190mm-long aluminium beams and an extension of 400mm that projects from the back of this assembly.

Its frontal part has two functions:

1.- The front side of the top section has a length of 760 mm, this length in combination with the 3º inclination of the truss structure, assures the correct degree of inclination for the line array.

2.- It acts as a reliable arm to fit the 2T chain hoist that lifts the Line Array System.

Its rear part has two functions:

1.- It allows users to fasten the safety hook of the brake winch. The hinge system at the base of the tower allows the mast structure to be lifted with very little effort. Just one-person operation!

2.- Once the tower has been fully assembled, the winch can be tightened slightly to provide a counterbalance stabilising effect.

UNIQUE DESIGN: GUIL’s engineers rose to the challenge of designing a base for the TMD-545/N that would serve as both the base of the Line Array tower and as the storage unit for all the parts and components of the tower when it is stowed. The truss sections and all the other parts, including the chain hoist and winch, are accommodated on the base (only 640×1190 mm in size), forming a compact block that prevents loss of components during storage and transport.

The base also has a spirit level to be used during set-up to level the tower with the screw jacks prior to lifting the Line Array.

LEGS AND STABILISERS: The legs and side stabilisers of the TMD-545/N, housed vertically on the base, are extendible to ensure that the tower has the largest, most stable footprint possible. Both the legs and the stabilisers are fitted with screw jack levellers, made entirely of steel with rubber feet on the discs, to make sure that the base is level before starting to lift the line array. In addition there are three more leveller jacks on the base of the tower, making a total of seven leveller jacks, all with chromed steel discs for maximum strength and reliability. The jacks are also fitted with double-speed threads, to allow the tower to be levelled as quickly as possible. When the legs and stabilisers are installed and extended, and the jacks are deployed to level the tower, they guarantee the 360º support that is essential for a device that operates close to large numbers of people.

TRANSPORT Four 100mm-diameter wheels with brakes are fitted on the base for easy transport, and the TMD-545/N is extremely manoeuvrable. A single technician can move the base containing all the components of the TMD-545/N wherever necessary. Just one person moving a whole line array tower to lift 500kg to 6.25 metres height: GUIL has it all thought out!

WINCH MOUNTING: The winch of the TMD-545/N is held on a special mounting which fits into the base for transport and storage, but during set-up is installed in its housing at the back of the tower to form an anchor point for the cable. This creates a brace to provide maximum strength and stability to the rigging tower, and greater support for the load when it is raised.

The crank handle of the brake winch, specially designed for lifting heavy loads, is detachable, in order to prevent any manipulation during the event.

TMD-545/N – THE ULTIMATE 6.25-METRE RIGGING TOWER

The TMD-545/N Rigging Tower complies with the requirements of safety according to the following Standards and Regulations:

▪ Directive for Machinery Safety 2006/42/CE

▪ DGUV 17 & 18

▪ DGUV Rule 115-002 (Formerly BGV-C1)

▪ DIN EN 17206 (Replaces DIN 56950-1)

▪ DIN EN 13814

When GUIL first introduced their TMD-545 line array tower, it was a trailblazer in the events sector, its success due to its inventive design; just one base carries the entire tower, reducing storage space and set-up times, and the tower is remarkably light for its weight and height performance. The current version has been improved over the years and is now produced in black, epoxy paint finish, to make its presence more discreet at concert venues.

Following the success of the TMD-545/N, GUIL’s in-depth market research of the needs of events professionals has allowed us to offer new towers and other products to supply similarly compact and original towers for technicians who need to lift bigger, heavier sound systems, such as our TMD-570.

TMD-545/N Technical Specifications

TMD-545/N Static Analysis- Certificate

RELATED PRODUCTS

| Maximum Height | 8 m |

|---|---|

| Maximum Load | 350 Kg |

| Height stowed | 1.99 m |

| Maximum Height | 6.5 m |

|---|---|

| Maximum Load | 400 Kg |

| Height stowed | 1.99 m |

| Maximum Height | 6 m |

|---|---|

| Maximum Load | 350 Kg |

| Height stowed | 1.63 m |

AT GUIL WE MANUFACTURE LIFTING TOWERS SINCE 1983

We use only the highest quality components that guarantee MAXIMUM SAFETY AND STRENGTH

SOMETHING ELSE FOR YOUR EVENTS

YOUR EVENTS

Start and finish-line arches & Frames for Advertising

Special sizes and shapes available