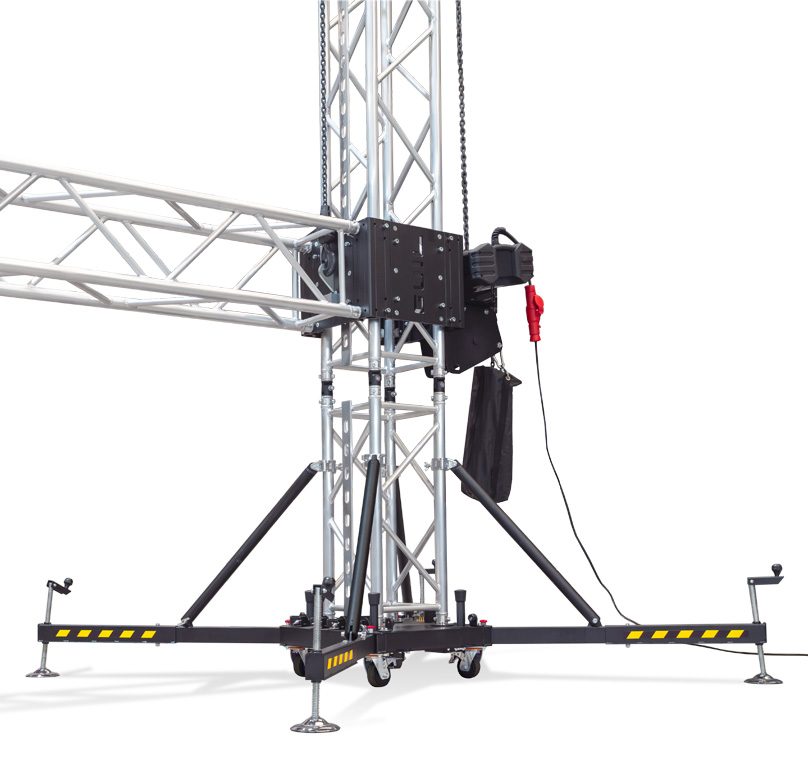

Ground Support tower

This Ground Support Tower is designed to lift loads of up to 800 kg, with a maximum working height of 8 m (total height of the tower: 8,39 m).

Its structure is made up of reinforced trusses with a 400 x 400 mm square profile and 3 mm thickness.

The sleeve block, fitted with a mounting for a motor, makes the motorised lifting and lowering of loads easy.

This tower has been manufactured to ensure maximum performance both indoors and outdoors, providing a robust, adaptable solution to a range of needs.

| SPECIFICATIONS | TMD-900/8 |

| Maximum Height: | 8.39 m |

| Maximum Load: | 800 kg |

| Mast Sections – Square Truss: | 400 x 400 x 3 mm (reinforced truss sections) |

| Folded dimensions: | 987 x 700 x 1760 mm |

| Base area: | Maximum: Ø4066 mm |

| Material: | Aluminium and Steel |

| Use: | For outdoor and indoor use. |

| Complies with Standards: | 2006/42/CE EN 17206 (Replaces DIN 56950-1) DGUV 17 & 18, DGUV Norma 115-002 (Formerly BGV-C1) |

| Net weight: | 254 kg |

| Colour: | Black and Aluminium |

Maximum height: 8,39 m (working height: 8 m) | Maximum load: 800 kg

The TMD-900/8 Ground Support tower is fitted with an advanced fall-prevention safety system, which prevents the structure from collapsing in the extreme case of the cable breaking.

The system consists of a rack that travels the length of one side of the truss sections and a safety bolt installed in the sleeve block. In the event that the cable breaks, the bolt engages automatically and enters in the nearest hole of the rack, immobilising the sleeve block and preventing it from falling.

VERTICAL TRUSS STRUCTURE

The TMD-900/8 tower is composed of 5 reinforced truss sections of 400 x 400 mm:

- Three 1 m sections:

– The section located in the base is connected via hinges to the rest of the sections;

– The uppermost section houses the headpiece;

– A third section, with no specific purpose, which forms part of the structure.

- One 2 m section: Also fitted with hinges, this section is easily connected to the truss on the base.

- One 3 m section.

The sections are assembled using UTR-10 connectors, which ensures safe, efficient assembly.

In this way, the vertical structure is set up, providing a robust, stable construction where the sleeve block can move safely.

The sleeve block is designed with three sides where horizontal lengths of truss can be assembled, allowing different structures to be configured according to the requirements of each project. Its versatility allows trusses both of 400 x 400 mm and of 290 x 290 mm to be connected.

The sleeve block moves smoothly and efficiently thanks to its 16 nylon wheels that reduce friction and minimise wear and tear, both on the tower and on the sleeve block itself. The wheels of this system act as guides, ensuring smooth movement and prolonging the useful life of the tower.

Thanks to GUIL’s innovative design, which incorporates a special mounting for a motor, the lifting and/or lowering process of the tower (vertical structure) and the construction (horizontal structure) is smoother and more stable. This characteristic allows the structure to be operated quickly and simply by a single professional.

This new GUIL sleeve block design offers excellent compatibility with different models and brands of motor, thanks to its adjustable internal slots, allowing the height to be adjusted according to the dimensions of the motor.

Another advantage of the new GUIL motor support is its compatibility with the sleeve block of the TMD-600 model, allowing the modular tower to be converted into a manual or motorised version, according to if it has a two-handled winch or the motor support.

(Note: Motor not included. We recommend using a motor with a load capacity of 1000 kg.)

The compact steel base has been designed to hold the components of the tower, except for the truss sections, in an extremely reduced space. This means that the tower is very practical and mobile, making its transportation and storage easy.

Following conversations with users of our towers during the development of the TMD-900/8, we have incorporated an innovative model of leg sockets. This through socket allows the length of the leg on one side to be shortened by inserting it further into the base than usual. This feature makes it possible to adapt the footprint of the tower to places with more limited space.

The headblock, consisting of two high-resistance 1290mm aluminium beams, is located in the uppermost 1m truss section. Its design allows it to be easily detached from the tower for storage in the base or setting aside on the ground during set-up, as well as facilitating the installation of the motor chain.

TELESCOPIC LEGS

The tower is fitted with 4 telescopic legs, each one with three different length settings. In their shortest version, the legs are 1180 mm long once assembled in the base. To increase the footprint and, with it, the tower’s stability, each leg has two extensions of 196 mm, which allows them to reach lengths of 1376 mm or 1572 mm as required.

Each leg has a leveller screwjack with double thread for quick, safe adjustment, as well as non-slip discs which prevent any movement during use, guaranteeing greater safety and stability.

4 STABILISING ARMS

Each leg is connected to the tower with a stabiliser arm, guaranteeing great solidity and resistance, two key properties of any lifting tower. This construction ensures the stability necessary for its use both in outdoor and indoor settings with high concentrations of spectators.

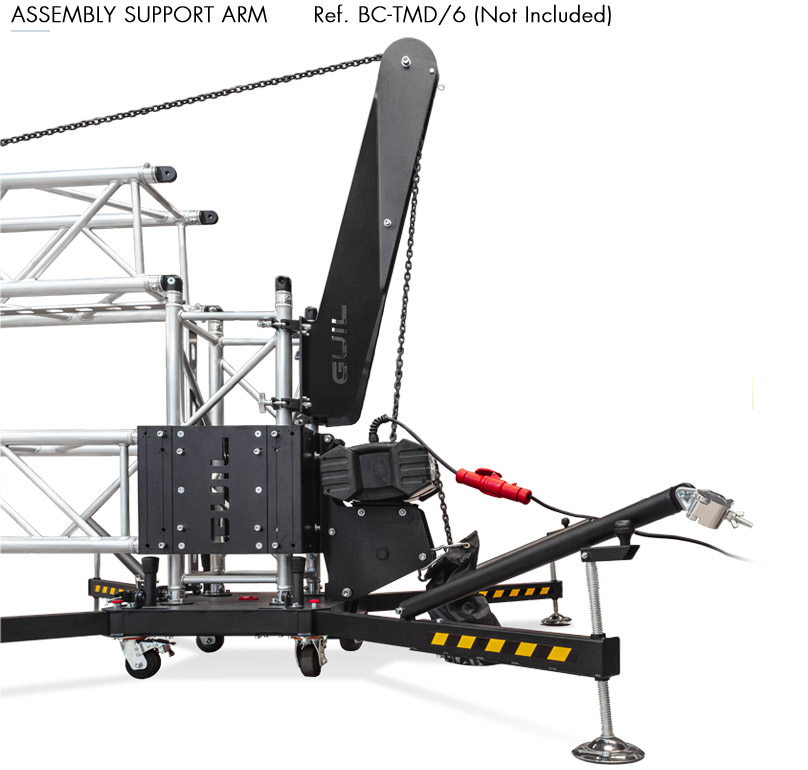

ASSEMBLY SUPPORT ARM BC-TMD/5 – OPTIONAL

To make the assembly of the TMD-900/8 easier, GUIL offers an optional accessory (Ref: BC-TMD/6), which is fastened to the base truss with clamps. This accessory provides a raised vantage point to lift the vertical truss structure, reducing the motor’s workload. This point of support can be used to lift a tower and then be fitted to the next, allowing the towers to be assembled one after the other.

GUIL – Technical Specifications – TMD-900

GUIL TMD-900 – Certificate

RELATED PRODUCTS

AT GUIL WE MANUFACTURE LIFTING TOWERS SINCE 1983

We use only the highest quality components that guarantee MAXIMUM SAFETY AND STRENGTH

SOMETHING ELSE FOR YOUR EVENTS

YOUR EVENTS

Start and finish-line arches & Frames for Advertising

Special sizes and shapes available