Compact design Line Array Tower

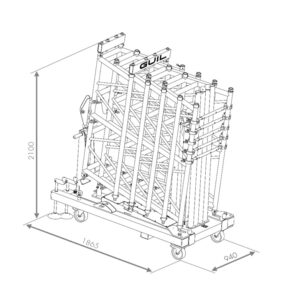

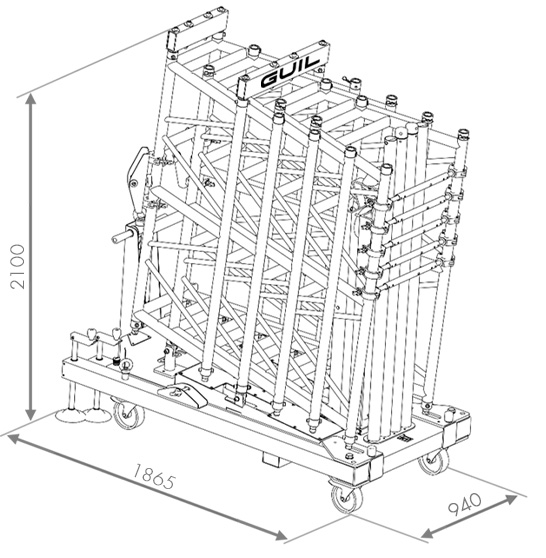

(Stowed volume: 3.68 m3)

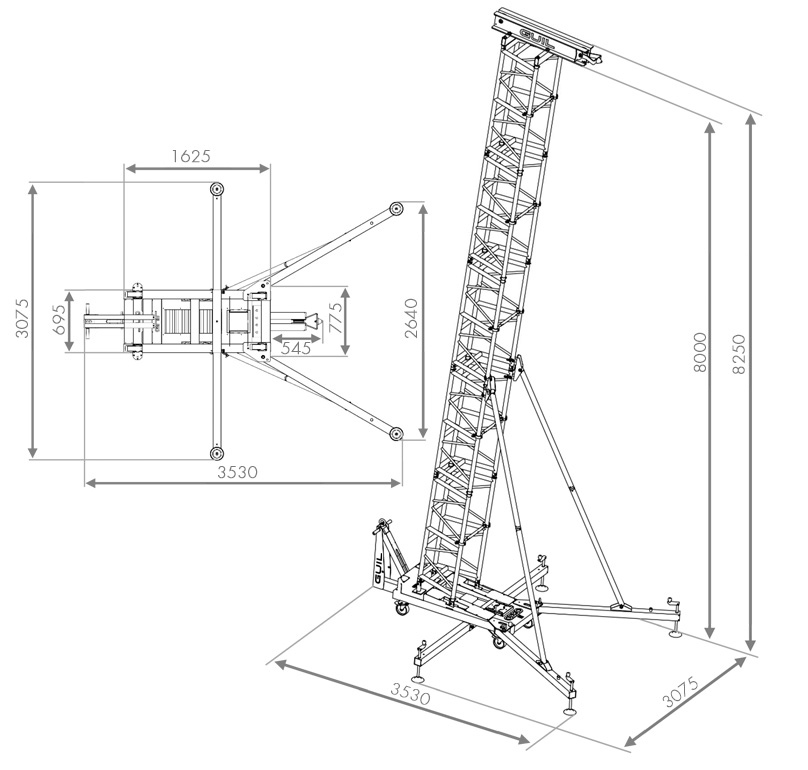

The TMD-570 Line Array Lifting Tower is a compact, exclusive design by GUIL, specially created to reliably lift Line Array systems of up to 800 kg (1,760 lb) to a maximum height of 8 metres (26 ft 3 in) using an electric motor. GUIL’s engineers have created a totally innovative tower, certified for outdoor use under European norm EN 13814.

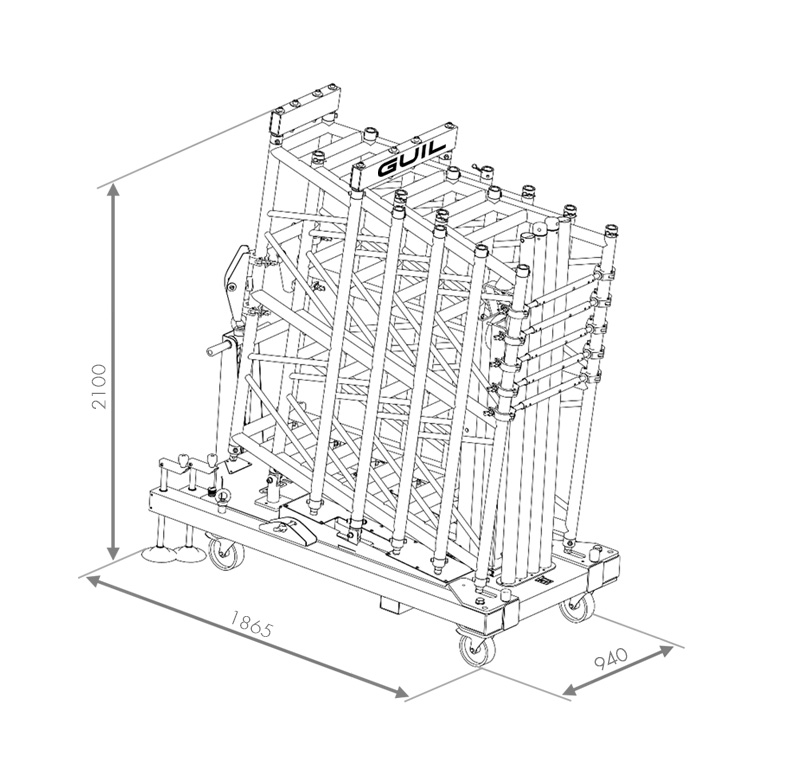

Its meticulous design offers quick and easy assembly. The TMD-570 tower is extremely manoeuvrable, all the components of the tower fit without spare parts in a single base (with a volume of just 3.68 m3 – 130 ft3), making it easy to transport and store.

The tower is supplied with the interactive application “TMD-570 APC” for its use outdoors, taking into account the maximum wind speeds permitted by applicable standards.

| SPECIFICATIONS | TMD-570 |

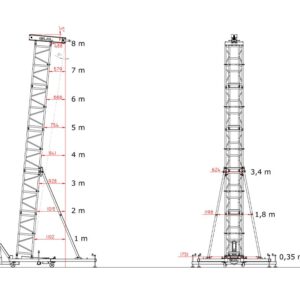

| Maximum Overall Height: | 8.25 m I 27 ft |

| Maximum Working Height: | 8 m I 26 ft 3 in |

| Maximum Load: | 800 kg I 1764 lb |

| Material: | Aluminium & Steel. BLACK Finish |

| Stowed dimensions (Compact Design) | Height: 2.10 m I 5 ft 11 in Base: 94 x 187 cm I 3 ft 1 in x 6 ft 2 in |

| Volume: | Everthing in 1 piece I 3.68 m3 I 130 ft3 |

| Use: | For OUTDOOR and Indoor use |

| Certified for outside use: | According to: EN 13814 |

| Checked for wind speed up to: 8 Beaufort | |

| Complies with Standards: | 2006/42/CE EN 17206 (Replaces DIN 56950-1) DGUV 17 & 18, DGUV Norma 115-002 (Formerly BGV-C1) |

| Net Weight: | 360 kg I 794 lb (All components included) |

| Interactive application: | “TMD-570 APC” (Included) |

Maximum height: 8 m (26 ft 3 in) / Maximum load capacity: 800 kg (1760 lb)

When GUIL launched their first compact line array tower, the TMD-545 (for 500kg up to 6.40m high) in 2003, it was a PIONEER in the industry, its wide popularity based on its ground-breaking design; cutting down on storage space and set-up times. The TMD-570 follows the innovative trail blazed by the TMD-545, and our extensive market research of the requirements of the events industry, to meet the increasingly frequent demands of professionals for similarly compact and original towers capable of lifting bigger sound systems.

QUICK AND EASY SET-UP: Familiar with the problems faced by technicians to install sound systems of these characteristics for outdoor events, GUIL have designed the TMD-570, which allows a single professional to raise the structure by means of an electric motor.

Its design allows the structure’s mast to be raised to the vertical position with no need to rely on four or five people. With the TMD-570 tower, a professional needs only two minutes help from a colleague to start to raise the mast before completing the lifting process with the motor.

PRACTICAL & COMPACT FOR STORAGE AND TRANSPORT: With its inventive construction and high performance, its quick set-up and reduced stowed dimensions in just one piece of 3.68 m3, and its ease of transport and handling, the TMD-570 has the right to be regarded as one of the most practical structures on the market. Just one technician can move the TMD-570 on its wheels, using the handlebar to steer it, from the lorry to the set-up location.

The TMD-570 tower is the perfect solution for events where a Line Array tower with a large lifting height and maximum load capacity is required and where storage space and transport are also an important factor. The TMD-570 is supplied with a chain bag (Ref. BLC-05) to keep the chain of the electric motor.

DESIGNED FOR OUTDOOR EVENTS: The TMD-570 was specially conceived for outdoor use (though, naturally, it may also be used indoors), and is supplied with an interactive application, the “TMD-570 APC”, which helps the user to calculate the maximum permissible wind speed, according to the EU norm (EN 13814) for this purpose, taking into account the weight and height for the line array to be used on each occasion.

MAXIMUM SAFETY AND RELIABILITY: For GUIL, the first priority at all times is the safety of everybody using or near our products. For this reason, we work only with the most up-to-date technological solutions and the highest-quality materials to fulfil the projects of our engineering department, and the TMD-570 is a clear example of this rule. The certified strength and stability of this tower, conceived and built to hold 800 kg of line array at a height of 8 metres, are achieved by its intelligent design and reinforced construction, and guarantee the protection of both the line array itself and, of course, of the public attending the event.

The TMD-570 rigging tower has been designed to be as quick and easy as possible to assemble, while at the same time making safety a priority. The front legs of the tower are attached to the base, and swing out to be anchored in their splayed position at the front of the tower. The side stabilisers are inserted into their housings and held in place with magnetic locking pins (Ref. RC-100/L).

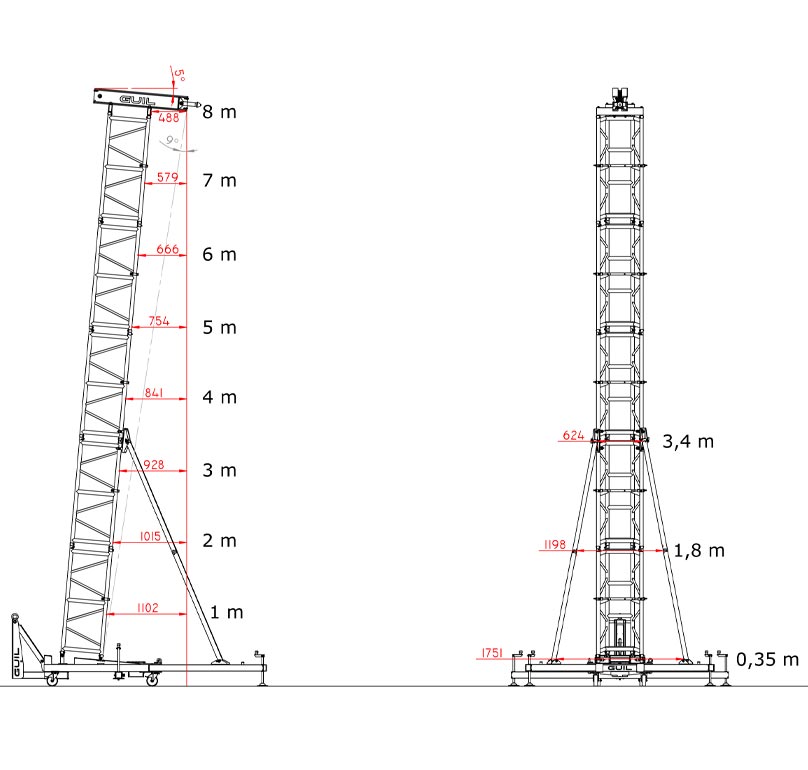

The truss sections of the TMD-570 are designed to be assembled horizontally, before being attached to the hinges on the base of the tower and raised into a vertical position with the electric motor (not supplied: we recommend using a 1000 kg capacity motor).

The tower is then levelled using the screw jacks on the legs and side stabilisers and the spirit level on the base. This system guarantees quick and easy assembly and take-down of the tower, which can be carried out by only two people.

The trapezoidal section truss stages were created in GUIL’s technical department with the aim of designing a high-strength lifting mast specifically for outdoor use which, at the same time, would be quick to assemble and would occupy as little space as possible with an eye to storage and to transport.

In addition to lifting the sound apparatus and raising the aluminium structure to its vertical position, the chain of the motor also acts as an auxiliary strut, giving the tower great solidity and resistance. NOTE: We recommend using a motor with the following specifications: Load capacity: 1000 kg I Chain length: 18 metres

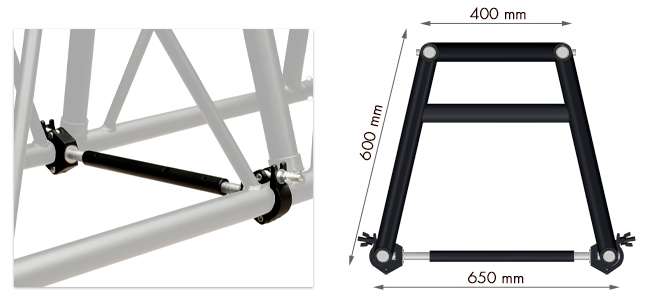

TRUSS SECTIONS: The mast section consists of five 1500mm sections of truss in a trapezoidal design (400mm wide at the back, 650mm at the front), which allows the sections to be stacked together vertically on the base for storage and transport. Three adjustable strengthening braces are supplied to reinforce the sections, and the truss sections are connected with zero play for maximum security. The truss sections of the tower have been specially designed by GUIL’s engineers to provide maximum strength and reliability, while also stacking together for storage and transport to occupy a mere 3.68 m3 when stowed on its wheeled base.

TRUSS SPACERS: Each truss section is supplied with an adjustable truss spacer to reinforce the sections and prevent deformation (5 truss spacers in total).

STRENGTHENING BRACES: The truss tower itself is equipped with two strengthening braces or brace bars to withstand large loads and maintain the stability of the structure. Each brace is secured with a brace fastener with double clamps to the trusses and to the front legs with specially-made brackets, to form a strong and stable unit.

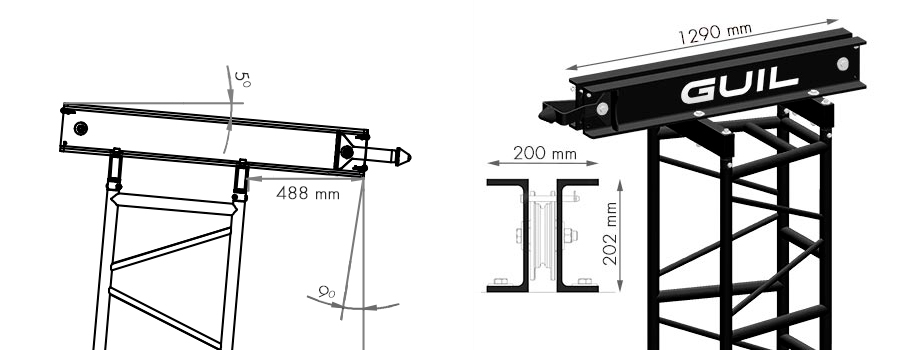

The head block consists of two 1290mm-long aluminium beams and, in combination with the 5º inclination of the truss structure, assures the correct degree of inclination for the line array. It can be detached from the tower to be stored in the base for transport, or also to be placed on the ground to assemble the tower and to install the chain of the motor. The headblock is fitted with a large silentblock to protect it when setting up and taking down the tower.

UNIQUE DESIGN: The base of the TMD-570 is the result of revolutionary design and pioneering execution, with the dual purpose of forming the foundation of the line array tower when it is in use, and accommodating all the components of the tower in one block for transport and storage, thus avoiding loss of components. The base (with dimensions of just 940×1865 mm) is fitted with custom-made nylon protectors to prevent damage from scratches or blows and to keep your TMD-570 in perfect condition, and also has a spirit level to help with the process of levelling the tower during assembly.

MOTOR MOUNTING: For the electric motor, GUIL have created a special mounting which fits under the base for transport and storage, but is pulled out to form an anchor point for the chain, which creates a brace to provide maximum strength and stability to the rigging tower, and greater support for the load.

LEGS AND STABILISERS: The folding legs are installed on the base, and the side stabilisers are housed in the side members of the base, they are fitted with leveller screw jacks that have reinforced nylon injection moulded spin handles (ergonomic design) with double thread and speed which facilitates the levelling task. Their non-slip foot plates ensure a perfect adjustment of the tower to the floor surface.

The legs and side stabilisers provide further support for the lifter and guarantee the 360º support that is essential for a device that operates close to large numbers of people.

TRANSPORT: The base is fitted with four 150mm-diameter wheels with brakes for easy transport, making the TMD-570 highly manoeuvrable, and the motor support includes a handlebar to steer it. A single technician can move the base loaded with all the components of the TMD-570 wherever necessary. Just one person moving a whole line array tower to lift 800kg to 8 metres height: who can resist that?

TMD-570 – THE ULTIMATE 8-METRE RIGGING TOWER

The TMD-570 Rigging Tower complies with the requirements of safety according to the following Standards and Regulations:

▪ Directive 2006/42/CE on machinery that establish “Essential health and safety requirements relating to the design and construction of machinery”. ▪ EN 13814: Fairground and amusement park machinery and structures.

▪ EN 13814: Fairground and amusement park machinery and structures.

▪ EN 17206 (Replaces DIN 56950-1) Entertainment technology – Machinery for stages and other production areas – Safety requirements and inspections.

▪ DGUV Regulations 17 & 18: Accident prevention regulation. Event and production facilities for scenic presentation.

▪ DGUV Rule 115-002: Staging and Production Facilities for the Entertainment Industry.

TMD-570 – THE ULTIMATE 8-METRE RIGGING TOWER

The TMD-570 Rigging Tower complies with the requirements of safety according to the following Standards and Regulations:

▪ Directive 2006/42/CE on machinery that establish “Essential health and safety requirements relating to the design and construction of machinery”.

▪ EN 13814: Fairground and amusement park machinery and structures.

▪ EN 17206 (Replaces DIN 56950-1) Entertainment technology – Machinery for stages and other production areas – Safety requirements and inspections.

▪ DGUV Regulations 17 & 18: Accident prevention regulation. Event and production facilities for scenic presentation.

▪ DGUV Rule 115-002: Staging and Production Facilities for the Entertainment Industry.

TMD-570 Technical Specifications

GUIL - Static Analysis & Certificate _TMD-570 Rigging Tower

RELATED PRODUCTS

| Maximum Height | 8 m |

|---|---|

| Maximum Load | 350 Kg |

| Height stowed | 1.98 m |

AT GUIL WE MANUFACTURE LIFTING TOWERS SINCE 1983

We use only the highest quality components that guarantee MAXIMUM SAFETY AND STRENGTH

SOMETHING ELSE FOR YOUR EVENTS

YOUR EVENTS

Start and finish-line arches & Frames for Advertising

Special sizes and shapes available